The Problem

About Biosolids

The biosolids problem and how we solve it.

An age-old problem that

has yet to be solved,

until now.

Biosolids Impact:

Community Health

Pathogen & Vectors

GHG Emissions

Soil Contamination

Landfill Odors

Soil Health

Nutrient Runoff

Aquatic Dead Zones

The Biosolids Problem is Getting Worse

-

Biosolids disposal is a major source of GHG emissions and a material cost to New Yorkers.

-

The biosolids disposal problem in NY is getting worse with no inexpensive solution in sight.

-

We create a “beneficial use” byproduct that destroys PFAS and other contaminants.

-

We solve a costly problem that local governments have with biosolids disposal.

-

Biosolids recycling options are becoming constrained by their contaminants.

Waste Not: How We Solve the Biosolids Problem

Click on an item to view an in-depth explanation.

- Destroys PFAS, VOCs, microplastics, pathogens, and other contaminants in biosolids.

- Achieves lowest emissions of any biosolids disposal method that remediates PFAS.

- Reduces GHG emissions from biosolids disposal and chemical fertilizer manufacturing.

- Sequesters beneficial carbon in soil where it is needed.

Ensuring our air emissions are safe, our GHG emissions are low, and our odors are impeccably managed are the primary factors that will determine our success with public utilities.

SBS employs benchmark air treatment to protect human health and our reputation.

- Building Design – Contains fugitive odor from biosolids receiving and processing.

- Pyrolysis – Separates PFAS and contaminants from biosolids.

- Thermal Oxidation – Staged combustion reduces NOx and removes PFAS and contaminants.

- High-efficiency Dry Cyclones – Recover most of the dried material.

- Wet Venturi Scrubber – Removes the remaining fine particles.

- Hydrated Lime Scrubber – Removes sulfur dioxide (SO₂) and neutralize odor compounds.

- Ammonia Scrubber – Removes ammonia (NH₄) odors.

- Dual-stage Bio-scrubbers – Polishes odors and further removesSO₂.

Biosolids have traces of many contaminants, including PFAS, that must be remediated.

- Pharmaceutical products, micro-plastics, hormones, cleaners, oils, fats, greases, VOCs and many other contaminants that make their way into sewage.

- These contaminants make it through the drying stage of our competitors and are present in all dried biosolids products that are currently sold and distributed nation-wide (i.e., Milorganite).

- In the SBS process, these contaminants are separated from the solids in the pyrolysis stage.

- Once in a gaseous form these contaminants are quickly destroyed by thermal oxidation.

Pyrolysis is a decontamination technology that works extremely well with biosolids.

- Dried biosolids are heated in an oxygen-free environment at over 1,100°F for up to 30 minutes which causes even the toughest contaminants to separate and become part of the syngas.

- Syngas is kept hot for the several seconds of its existence to ensure molecules don’t start reconnecting and forming air emissions.

- PFAS compounds are liberated from solids into a volatile gas state where they are destroyed by thermal oxidation (2,300°F).

- Syngas is thermally oxidized in stages to achieve the lowest NOx emissions possible.

Pyrolysis has been similarly used to remediate soil contaminants for decades, albeit without the advanced air treatment solution that we employ.

The USEPA Interim Guidance released April 8, 2024 (https://www.epa.gov/pfas/

If your question is not answered, don’t hesitate to contact us.

Carbon Fertilizer comes in four particle sizes:

Granular SGN 400

(average diam. 4mm)

Designed for agricultural and soil restoration applications: drop-in substitute for chemical fertilizers.

Granular SGN 200

(average diam. 2mm)

Designed for farm, lawn & garden, landscaping, horticulture, sod farms, soil restoration, and soil remediation: drop-in substitute for chemical fertilizers.

Greens Grade SGN 80

(average diam. 0.8mm)

Designed for golf courses and applications that require a smaller particle size: drop-in substitute for chemical fertilizers.

Seed Coating – Powder

(average diam. <0.5mm)

A powder used in coating seeds, plant propagation, and other applications that require a very small particle size.

Climate Friendly Process

The SBS facility employs a proprietary climate friendly process that beneficially recycles biomass and protects human health and the environment.

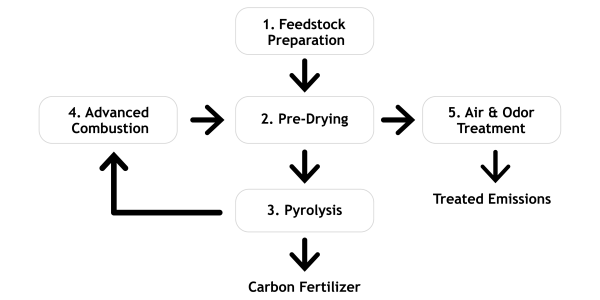

Feedstock Prep

Biosolids and wood waste are sized, mixed, and sent to dryer.

Pre-Drying

Feedstock is dried utilizing heat generated from advanced combustion.

Pyrolysis

Dried feedstock is heated without oxygen to separate PFAS and other VOC contaminants from Carbon Fertilizer.

Advanced Combustion

Remediates PFAS and other contaminants separated by pyrolysis and generates heat for pre-drying feedstock.

Air & Odor Treatment

Employs benchmark air treatment to manage air emissions, odors, and our reputation.

Climate Change Tool

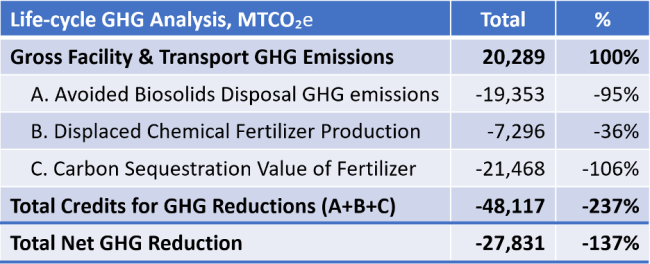

Carbon Fertilizer’s production and use generate three GHG emissions offsets, or credits, based on avoided and sequestered GHG emissions.

Avoided Biosolids Disposal GHG Emissions Credit

- Bringing biosolids to the SBS facility avoids GHG emissions that would otherwise be incurred through current biosolids disposal practices in New York. This includes the methane and nitrogen dioxide emissions associated with decomposition, GHG emissions related to transport, as well as the relative share of GHG emissions that incinerators and other disposal practices contribute.

- Generates a 95% GHG reduction credit relative to SBS facility GHG emissions.

Carbon Sequestration Credit

-

Carbon Fertilizer use sequesters carbon in soil where it is needed to improve water and nutrient retention in perpetuity. Carbon Fertilizer contains approximately 30% fixed carbon that is resistant to degradation for centuries (i.e., petrified).

-

Generates a 106% GHG reduction credit relative to SBS facility GHG emissions.

Displaced Chemical Fertilizer Production Credit

- Carbon Fertilizer use displaces chemical fertilizer as a direct substitute in crop production and avoids GHG emissions associated with chemical fertilizer production and transportation.

- Generates a 36% GHG reduction credit relative to SBS facility GHG emissions.

Carbon Fertilizer’s life cycle GHG Analysis yields a 137% net GHG reduction after deducting SBS facility and transport GHG emissions.

In the GHG emissions context, being negative is a very positive thing as traditional energy has a positive GHG footprint and renewable energy, like solar and wind, typically have a carbon neutral life cycle GHG footprint.