Carbon Fertilizer is Super Biochar loaded with organic matter, carbon, and nutrients that is directly applied to soil, and blended with other fertilizers and soil amendments.

Carbon Fertilizer makes restoring soil carbon, organic matter, and biology simple and easy.

-

Dry granular particles provide a drop-in substitute for chemical fertilizers.

-

Inoculation with nutrients and organic matter is not required like wood biochar.

-

Compatible with dry fertilizer spreaders on farms, golf courses, and in households.

The Benefits of Carbon Fertilizer™

Carbon Fertilizer™ is a revolutionary bio-fertilizer made entirely from wasted bio-resources that is designed to sequester carbon and rejuvenate soils.

Made in the USA from locally sourced organic matter, carbon, and nutrients (biosolids and wood).

Sequesters carbon in soil, enhancing hydration and reducing erosion.

Pyrolysis process eliminates PFAS, VOC contaminants, odors, and pathogens found in biosolids.

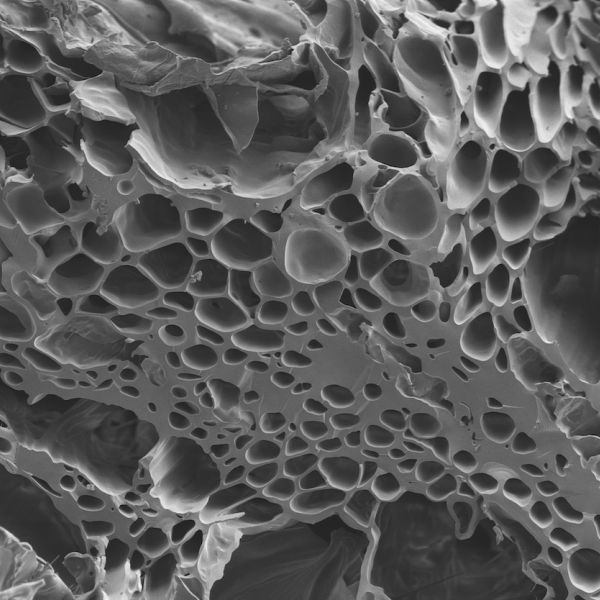

High cation exchange capacity (CEC) improves nutrient capture, storage, and transfer to roots.

Minimizes nutrient losses from leaching and runoff, reducing the need for additional fertilizers.

Gradually releases nutrients to plant roots as needed, supporting healthy growth.

Promotes robust root growth by providing essential nutrients, oxygen, and moisture.

Accelerates early-stage plant development and boosts crop yields.

Organic matter enriches soil and fosters microbial and fungal proliferation.

Environmentally friendly process and soil application result in a negative greenhouse gas footprint.

Sequesters its weight in greenhouse gas emissions when applied to soil, aiding in climate mitigation.

How It Works

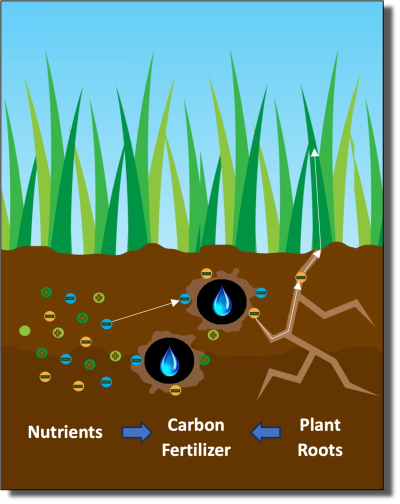

Carbon Fertilizer is more than a common fertilizer. It’s Super Biochar that delivers nutrients to plants and feeds soil!

-

Delivering nutrients to plants.

Its high cation exchange capacity (CDC) attracts and interacts with nutrients that are co-applied, or already in the soil; pulling them into a porous structure to avoid leaching and runoff. Roots are attracted to the oxygen, water, and nutrients in the biochar, and seek it out and tap it in the soil. Nutrients and moisture are released “on demand” as the plant requires them for growth.

-

Feeding soil.

Carbon Fertilizer’s high organic matter and porosity create an all-inclusive hotel package for microbes and fungi which fosters their proliferation in the soil. Organic matter feeds the microbes and fungi to improve moisture content and nutrient retention. Carbon Fertilizer’s porous structure provides a place for microbes and fungi to replicate after feasting on organic matter.